APPLICATION DE SCELLANT POLYURÉTHANE (FIPG)

Application du scellant en polyuréthane Form-in-Place (FIPG) ou technologie d'application du scellant liquide Cure-in-Place (CIP), également appelée technologie de gasketing.

La technologie FIPG est de plus en plus utilisée à la place des joints en caoutchouc traditionnels pour améliorer les propriétés d'étanchéité et de fournir une étanchéité sans soudures.

One of the main field is a manufacture of the electric cabinets, distribution boxes (DB boxes), electric enclosures. The doors of the boxes have different sizes and different dimensions of PU foamed sealing are required. It is possible to change dimensions of the cure-in-place gaskets in the range of 6mm to 20mm and modify density of the gaskets, depending of the doors dimensions and sealing properties in order to reach comfortable opening and closing of the doors of electric DB boxes with saving insulating requirements.

Our machinery can be equipped with three-component PU applying system, in case of production the doors of electric enclosures with glass windows. It is possible to apply both PU foam gasket and 2-component PUR glue to stick glass window in the same FIPG technological process. Manufacturers of PU adhesive system offer solution where used two components A (A and C) and common component B. Our machine can apply seamless foamed PU gasket by mixing A and B, and thixotropic 2-component PUR by mixing C and B to bond glass to steel.

Our machinery can be equipped with three-component PU applying system, in case of production the doors of electric enclosures with glass windows. It is possible to apply both PU foam gasket and 2-component PUR glue to stick glass window in the same FIPG technological process. Manufacturers of PU adhesive system offer solution where used two components A (A and C) and common component B. Our machine can apply seamless foamed PU gasket by mixing A and B, and thixotropic 2-component PUR by mixing C and B to bond glass to steel.

Our machinery can be equipped with three-component PU applying system, in case of production the doors of electric enclosures with glass windows. It is possible to apply both PU foam gasket and 2-component PUR glue to stick glass window in the same FIPG technological process. Manufacturers of PU adhesive system offer solution where used two components A (A and C) and common component B. Our machine can apply seamless foamed PU gasket by mixing A and B, and thixotropic 2-component PUR by mixing C and B to bond glass to steel.

Our machinery can be equipped with three-component PU applying system, in case of production the doors of electric enclosures with glass windows. It is possible to apply both PU foam gasket and 2-component PUR glue to stick glass window in the same FIPG technological process. Manufacturers of PU adhesive system offer solution where used two components A (A and C) and common component B. Our machine can apply seamless foamed PU gasket by mixing A and B, and thixotropic 2-component PUR by mixing C and B to bond glass to steel.

FIPG technology is widely used in the street lamp housing production, where design of the outdoor lamp post lanterns requires 3D applying. Our machinery is equipped with 3D moving system, controlled with SIEMENS CNC operation system, allowing to reach accurate applying liquid polyurethane gaskets with high speed. Gluestream machinery can be installed in manufacturing lines, connected with any types of robotic arms and manipulators. PU formed-in-place gaskets have a high curing speed, allowing to work in fully automatic mode.

Nous savons à quel point l'environnement pur est important. Afin de réduire l'utilisation de solvants lors du nettoyage de l'injecteur, nous avons créé notre équipement avec un système de nettoyage à l'eau.

Nos ingénieurs améliorent quotidiennement notre équipement pour fournir à nos clients des équipements FIPG de haute qualité.

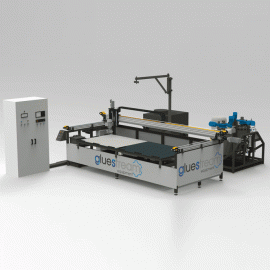

Vous pouvez vous familiariser ci-dessous avec l'équipement Gluestream pour l'application des scellants et des produits d'étanchéité sur le contour:

FIPG 2.1 FOAM CNC

Équipement d'application de scellant polyuréthane pour armoires électriques

FIPS 2.1 SEALANT CNC

Équipement d'application de mastic d'étanchéité polyuréthane à deux composants