ADHÉSIFS PUR THERMOFUSIBLES ET SYSTÈMES PSA

La technologie de collage de revêtements en rouleau sur les matériaux plats à l'aide d'adhésifs pur à fusion et PSA

What PUR hot melt technology is?

Hot melt polyurethane reactive adhesives react with a moisture of the bonded materials or with a moisture in the air. There are two stages of curing PUR hot melt: first stage is a physical effect of cooling down and solidification of the liquid adhesive, second stage is a chemical reaction of complete curing, allowing to reach high bonding properties. PUR adhesives have high water and temperature resistance, there is no chance to re-melt it, that makes PUR using in various industrial fields.

Reactive PUR hot melt adhesives are used, for example, in bonding different types of plastic materials, in flat lamination PVC and steel sheets with decorative PVC foils, in furniture parts production, textile industry for cleaning sponges manufacturing, automotive industry, woodworking industry, wooden parquet manufacturing, PVC windows profile wrapping. Compared to traditional hot melt adhesives, having a flat molecular structure, PUR has a 3D molecular lattice, penetrating the bonded materials and “stitches” them together. Due to the properties of the PUR adhesive, glued materials can be used in difficult weather conditions.

But magnificent properties of the PUR Hot melt adhesive require a high quality of adhesive applying machinery to be using. Adhesive applying system must be fully hermetic to prevent curing reaction inside of machinery. It is too important to follow a technological process to get a good result.

-High temperature resistance (up to 140 degrees);

-High elasticity;

-High moisture resistance and resistance to various cleaning agents;

-Safety of the adhesive using in hygienic products and various home using products;

-High bonding performance is achieved with low adhesive consumption;

-fast initial durability, allowing to use PUR adhesive in automatic process;

-solvent free technology to save environment and three-fold reduction of the logistics costs associated with transportation and storing of the adhesive;

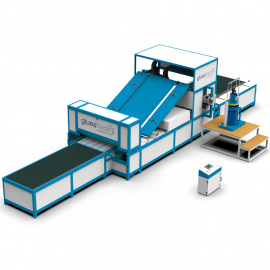

Gluestream offers machinery and technological process design for individual clients. Our roller coaters GLUESTREAM FLM-1500 are used for PVC sandwich panels manufacturing, HPL sandwich panels manufacturing in PVC doors production, decorative steel sandwich panels for steel security and fire-proof doors production.

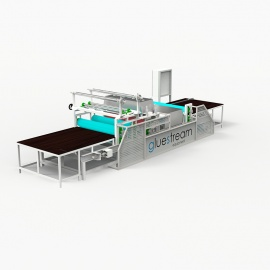

Nos unités FLM-1100 1-C PUR SPRAY et FLM-1100 SPRAY PUR HOT MELT avec la méthode de pulvérisation de colle sont utilisées dans l'industrie textile, par exemple dans la production d'éponges de nettoyage.

FLM VAl Singlesided Flat Lamination Machine

FLM SPRAY

You can discover Gluestream machinery for HOT MELT PUR & PSA FLAT LAMINATION TECHNOLOGY precision applying right here below:

FLM-1100 1-C PUR SPRAY

Ligne de production d'éponges de cuisine par pulvérisation d'adhésif PUR à un composant

FLM-1100 SPRAY PUR HOT MELT

Ligne de production d'éponges de cuisine par pulvérisation d'adhésif thermofusible

FLM-1500 HOT MELT PUR FLAT LAMINATING LINE

Ligne de laminage (contre-collage) sur la face avec l'utilisation des adhésifs PUR thermofusibles.