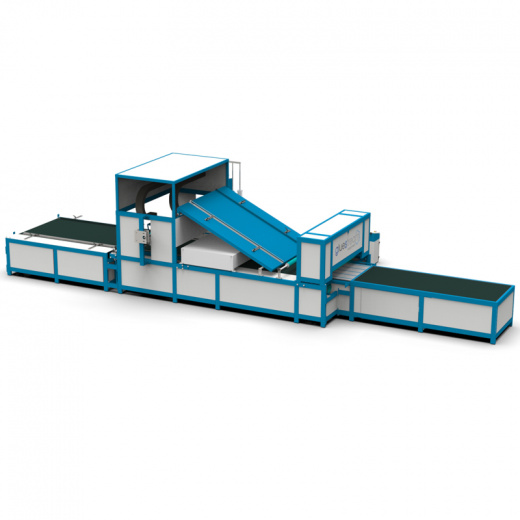

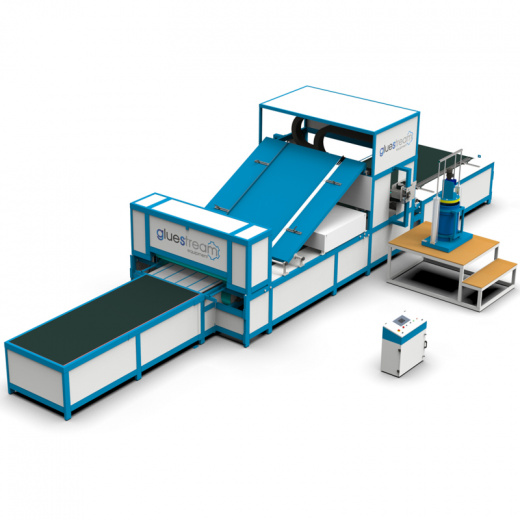

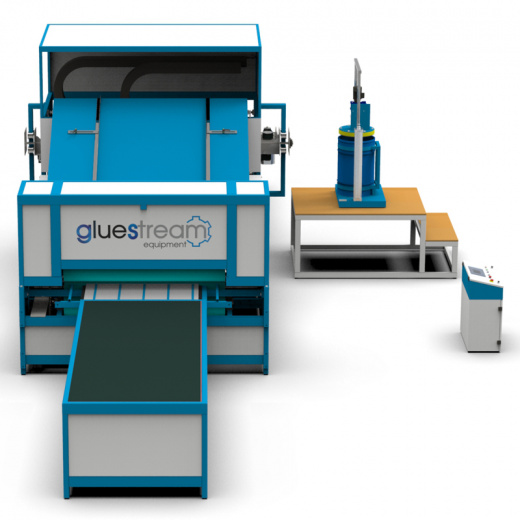

FLM-1100 SPRAY PUR HOT MELT MACHINE DE FABRICATION D'ÉPONGES À VAISSELLE

Technologie: ADHÉSIFS PUR THERMOFUSIBLES ET SYSTÈMES PSA

FLM-1100 SPRAY PUR HOT MELT MACHINE DE FABRICATION D'ÉPONGES À VAISSELLE

Technologie: ADHÉSIFS PUR THERMOFUSIBLES ET SYSTÈMES PSA

DESCRIPTION

Avantages de la méthode

- solvent free adhesive technology;

- fast curing;

- presses are not required;

- possibilities to cut the mat on pieces right after cooling down;

- low glue consumption;

- safety for the personal.

Gluestream FLM-1100 SPRAY se compose de:

- Roll unwinding unit;

- Belt conveyor;

- Adhesive applying unit with movable spraying heads;

- Hot Melt PUR drum melting station;

- Control system based on SIEMENS PLC;

- Heating tunnel;

- Inclined table for elastic polyurethane foam boards feeding;

- Roller press;

- Output table.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.